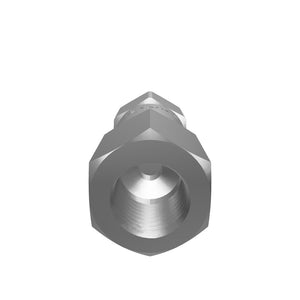

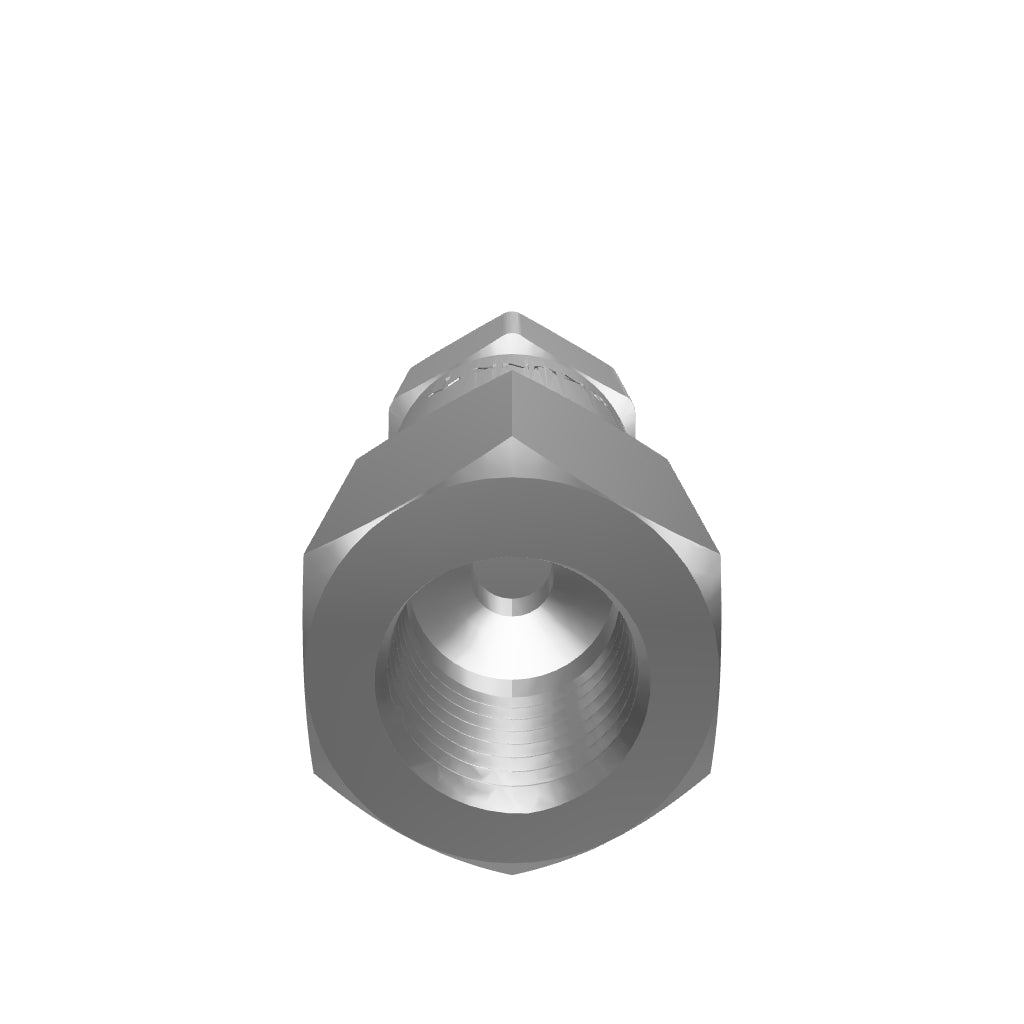

Upgraded Check Valve for Downstream Chemical Injectors w/ Skunk Hastelloy Spring

Upgraded Check Valve for Downstream Chemical Injectors w/ Skunk Hastelloy Spring

Check Valve for General Pump Downstream Chemical Injectors: Comes with Stainless Adapter and 1/4 barb - just screw into your General Pump Injector and start spraying! Increase efficiency and longevity...

-

Product details

Check Valve for General Pump Downstream Chemical Injectors:

Comes with Stainless Adapter and 1/4 barb - just screw into your General Pump Injector and start spraying!

Increase efficiency and longevity of your Downstream Injector

If you're using a General Pump Downstream Chemical Injector, you may want to consider adding a Skunk Check Valve to your setup. Not only does it help prolong the life of your injector, but it can also improve the strength of your chemical mix.

How is the Skunk different? Hastelloy... What is Hastelloy? Good question...

HASTELLOY C-276 is a nickel-chromium-molybdenum alloy with universal corrosion resistance unmatched by any other alloy. It has outstanding resistance to a wide variety of chemical process environments including ferric and cupric chlorides, hot contaminated mineral acids, solvents, chlorine and chlorine contaminated (both organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, sea water and brine solutions and hypochlorite and chlorine dioxide solutions.

HASTELLOY C-276 is a nickel-chromium-molybdenum alloy with universal corrosion resistance unmatched by any other alloy. It has outstanding resistance to a wide variety of chemical process environments including ferric and cupric chlorides, hot contaminated mineral acids, solvents, chlorine and chlorine contaminated (both organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, sea water and brine solutions and hypochlorite and chlorine dioxide solutions. -

Product technology

TLDR: The spring inside the Skunk Check Valve is made of Hastelloy, therefore it's highly resistant to corrosion.

This is a special upgrade exclusive to our model.

What Downstream Injector Does The Skunk Check Valve Connect To?

For the best results, we recommend using the 2.1 or 2.3 General Pump Hi Draw Injector in conjunction with the Skunk Check Valve. This injector is the one that we use on all our machines and has proven to be reliable and efficient. It is also the only chemical injector that the supplied adaptor will interface with. Attempting to install it on another type of injector may result in breaking the fitting and rendering it unusable.

Will This Check Valve Give Me A Hotter Mix?

In addition to increasing the longevity of your injector, using a Skunk Check Valve can also help improve the effectiveness of your chemical mix. With a stronger chemical mix, you can clean porous surfaces, such as those with black algae stains, faster and more efficiently.

We've had a few prototypes in the field for months, still running strong, and the reports are its delivering a hotter mix than any stock downstream injector could. We don't have the exact numbers yet, but we will be running tests in the coming months and will post them here. The mix is definitely hotter, and the Skunk Test Pilots that are the most vocal about loving this valve are using 8 gpm and 10 gpm machines. The volume these larger GPM machines put out dilutes a stock downstream injector mix heavily, and the Skunk Check Valve has shown to add back the concentration of chemical they lost.

How to Use Check Valve for General Pump Downstream Chemical Injectors

To use the Check Valve, simply follow the instructions provided in the video below.

*These check valves will last longer than a normal downstream injector, but like everything Im sure will eventually need to be replaced. That being said, we are flushing them out multiple times per day with the Smart Stream so ours are taken care of. They are not trashed and not left to soak in hot bleach. I recommend you flush yours as well.

*There is no warranty for anything that touches bleach, if it breaks, buy another one.

Upgraded Check Valve for Downstream Chemical Injectors w/ Skunk Hastelloy Spring

$12.99 SHIPPING ON MOST ORDERS

ABOUT

Upgraded Check Valve for Downstream Chemical Injectors w/ Skunk Hastelloy Spring

The Complete Guide

How To Actually Wash

Revolutionize your pressure washing business with How To Actually Wash. Unlock expert techniques, insider tips, and proven strategies to tackle every job. Stop guessing—accelerate success. Join thousands who’ve transformed their careers with this in-depth, game-changing course.