Hey guys, Cody from Southeast Softwash here! Today, I’m excited to share a simple yet powerful mod for your softwash system: the Skunk Downstream Injector Upgrade. Whether you’re running a pressure washing or softwashing setup, this piece of kit can make a world of difference in terms of reliability, chemical flow, and ease of maintenance.

Let’s dive into the details and why you need to add this to your setup.

The Problem with Traditional Downstream Injectors

Your standard downstream injector does its job but comes with some common issues:

- Corrosion and Malfunction: Over time, bleach and other chemicals cause the ball and spring mechanism inside the injector to corrode. This can lead to clogs, stuck components, and unreliable performance.

- Low Chemical Flow: Traditional injectors have smaller orifices, limiting the chemical mix ratio, meaning your bleach mix isn’t as strong as it could be.

- Field Repairs: Fixing a stuck check valve in the field often involves poking at it with a tool and hoping for the best. While this works temporarily, it’s not a long-term solution.

Why the Skunk Injector Upgrade is a Game-Changer

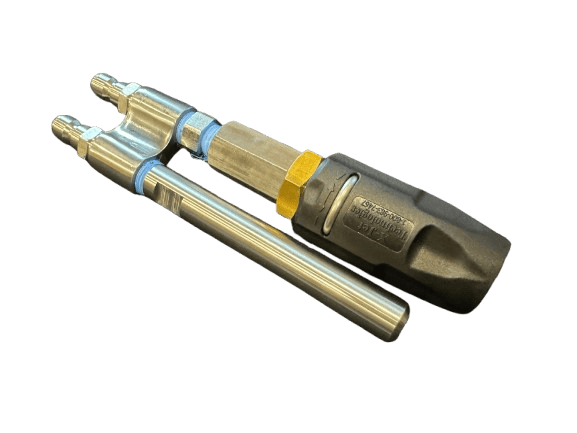

The Skunk Downstream Injector solves all these problems and more. Here’s what makes it stand out:

1. Superior Build Quality

The Skunk Injector uses stainless steel components and a Hastelloy spring, which is highly resistant to bleach corrosion. Unlike the flimsy spring in traditional injectors, this one lasts much longer—up to a year or more without maintenance.

2. Increased Chemical Flow

With its larger design and improved internal mechanics, the Skunk Injector pulls more fluid through the system. This means:

- Hotter bleach mixes for tougher cleaning jobs.

- Faster, more effective softwashing with less effort.

3. Easy Field Serviceability

Unlike the traditional injector, the Skunk Injector is designed to be field serviceable. You can take it apart, clean it, and reseal it in minutes. No more replacing cheap parts or dealing with makeshift repairs.

How to Install the Skunk Injector Upgrade

-

Remove the Old Injector:

- Locate your existing downstream injector on your equipment.

- Detach it from the system using quick connects.

-

Discard the Check Valve:

- Open the injector and remove the small ball and spring mechanism.

- Toss it (or, as we like to say, “Yeet it into the fire pit”).

-

Install the Skunk Injector:

- Attach the Skunk Injector in place of the old mechanism.

- Connect your chemical pickup line to the barb fitting.

-

Test the System:

- Run your system to ensure everything is working smoothly. You’ll immediately notice the improved flow and stronger chemical mix.

Why You Should Upgrade Today

For professionals in the pressure washing and softwashing industry, reliability and performance are non-negotiable. The Skunk Downstream Injector Upgrade provides:

- Better chemical ratios for tougher jobs.

- Long-lasting durability with corrosion-resistant materials.

- Simplified maintenance, saving you time and frustration.

At a price point that delivers incredible value, this upgrade is a no-brainer for anyone looking to optimize their softwash setup.

Ready to Upgrade?

Head over to SoutheastSoftwash.com and grab your Skunk Downstream Injector Upgrade today. Trust me—this little mod will revolutionize the way you work.

Stay tuned for more tips, tricks, and product updates in our next video! See you out in the field.