Hey, Southeast Softwash here! Today, we're pulling back the curtain on a game-changing tip that every soft wash business owner should know. If you’re still using a batch system, it might be time to consider switching to a blend system. This simple change has been the biggest efficiency booster for our operations, allowing us to tackle multiple jobs per day without the hassle and guesswork of manual adjustments.

Let’s dive in and look at why blending is the future of soft washing, and why it might be the right choice for you!

The Problem with Batch Systems

Fifteen years ago, I was just starting out in the soft wash business, primarily doing roof cleanings. Like most beginners, I used a batch system, a setup with a single tank where you manually mix your Sodium Hypochlorite (SH), water, and surfactant. This approach works fine if you're doing one job a day, but it quickly becomes inefficient if you have a multi-job schedule.

With a batch system, you’re constantly adjusting the chemical ratios, adding SH or water as needed. You’re also left with the issue of excess mix that either goes to waste or requires adjustment for the next job. For example, if you finish a roof wash and still have 20 gallons of mix left, you might add water to lower the ratio for a house wash. While this workaround can work, it's time-consuming and often results in wasted product.

The Efficiency of Blend Systems

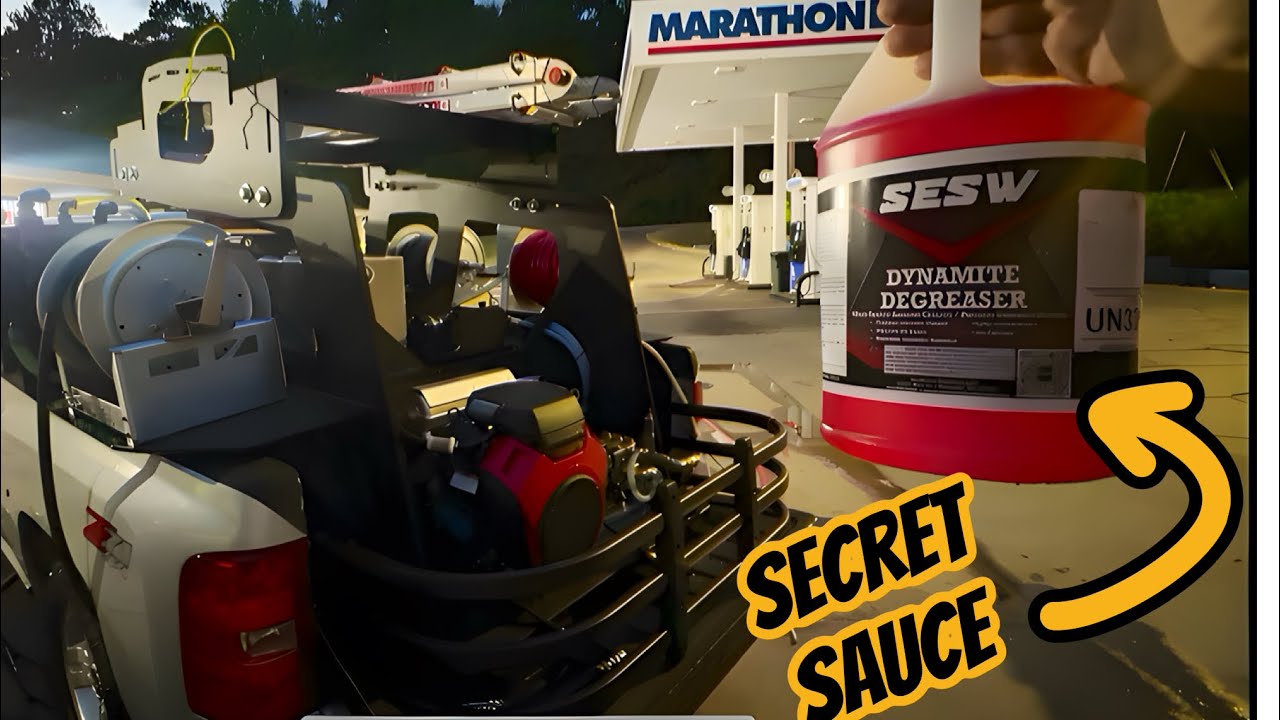

The blend system solves these problems by allowing you to adjust chemical ratios on the go. Instead of one tank, you have three—one for bleach (SH), one for water, and one for surfactant. This setup enables you to use a blending device to dial in the right mix as you work, ensuring that you’re not wasting product or time. No more stopping to remix; you simply adjust the valves to the ratios you need for each job.

Transitioning to a blend system was a turning point for us. I saw the difference in efficiency immediately, especially on those multi-job days. With a blend system, you’re no longer guessing how much mix you'll need for each job—you just adjust as you go, and you’re done!

Why Metering Valves Make All the Difference

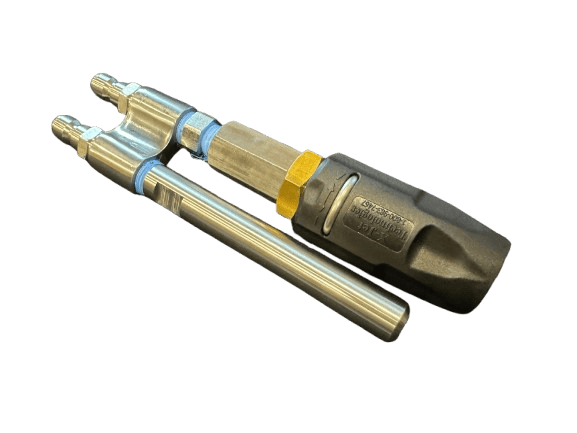

The key component in a blend system is the metering valve. Metering valves allow for precise control over the chemical mix. However, not all valves are created equal, and we learned that the hard way. Initially, we used standard ball valves and then upgraded to Pentair valves, but we soon encountered quality issues, like hairline cracks that couldn’t be detected until they started leaking.

After some trial and error, we switched to GF metering valves. Unlike standard valves, these are designed specifically for accurate metering, making them perfect for soft washing. They’re built with a tighter gradient, providing better control over flow rates, which is exactly what you need for precise chemical mixes.

How to Set Up a Blend System for Your Soft Wash Business

Setting up a blend system is straightforward, but you will need:

- Three Tanks – One for each component: SH, water, and surfactant.

- Blending Manifold – Connects all three tanks to allow for easy mixing.

- Metering Valves – We recommend GF valves for their accuracy and durability.

With this setup, you can adjust the flow from each tank based on the job requirements. Dial in the bleach for a strong roof wash, or reduce it for a gentler house wash—all without ever having to dump or remix.

Ready to Level Up Your Soft Wash Skills?

Switching from batch to blend systems has been one of the best decisions for our soft wash business. If you’re ready to make the change or simply want to deepen your skills in soft washing, Southeast Softwash’s Softwash 101 Class is here to help. Our comprehensive training will guide you through everything from equipment setup to job efficiency. We offer in-person training at our headquarters, or you can choose our video training for a flexible, remote option.

Don't miss this opportunity to increase your productivity, save time, and cut down on wasted materials. Join our Softwash 101 Class today to start maximizing your efficiency and profitability!