What’s up, guys? It’s already January 15th, and we’re halfway through the month. While the weather is still mild down here, it’s getting colder at night, so I hope you’re making the necessary preparations—especially for those of you up north dealing with snow.

Today, I wanted to take a moment to walk you through our trailer build process. We have some freshly built trailers ready to go and a blank one that’s about to be assembled, so this is a perfect opportunity to show you what sets a Southeast Softwash trailer apart from others in the market.

This isn’t about knocking other companies—there are plenty of solid setups out there. But we’ve developed our own way of doing things, refining it over the years to ensure our trailers are built to the highest standards. Let’s take a closer look.

The Foundation: The Trailer Frame

Every great build starts with a solid foundation, and for us, that means the trailer frame itself. We don’t just buy off-the-shelf trailers; ours are custom-built to our specifications down in South Alabama. Here’s what makes them unique:

-

6x12 Tandem Axle Design – Provides a stable and balanced platform.

-

Brakes on One Axle – Comes with a brake controller for added safety.

-

Square Tubing Construction – No angle iron here! Our trailers feature square tubing all the way around for maximum durability.

-

Pressure-Treated Floor – Helps resist water damage and extends the trailer’s lifespan.

Once the trailers arrive at our facility, we start by cleaning them off and prepping them for fabrication.

Custom Fabrication: Reinforcing the Structure

The next step is where we add our own touch. We do extensive fabrication to reinforce the trailer and make it ideal for softwashing applications.

-

Cross Bracing & Interior Welding – We add additional supports throughout the trailer to create an overbuilt, rugged structure.

-

Tank Bump Stops – Our water tanks sit perfectly in place, thanks to precisely positioned pegs that prevent movement.

-

Pre-Drilled Mounting Panels – These panels make it easy to install additional equipment like water hose diverters and pump shelves.

It’s a ton of fabrication work, but we’ve been doing this long enough that we have templates in place, making the process efficient and repeatable.

Corrosion Protection: Primer, Raptor Liner & Sealing

Since softwashing involves bleach and other corrosive chemicals, protecting the trailer from rust and deterioration is critical. We take extra steps to ensure our builds hold up for the long haul:

-

Primer Application – After fabrication, we thoroughly prime all metal surfaces.

-

Raptor Liner Coating – This tough, durable coating is similar to Linex and provides an extra layer of protection.

-

Sealing Exposed Tubing – We cap off any exposed tubing to prevent moisture from getting inside and causing rust.

-

Floor Protection – We even spray over the pressure-treated floor for additional durability.

This level of detail ensures your trailer will stand up to harsh conditions in the field.

Assembly: Bringing It All Together

Once the trailer is prepped, it moves to the assembly location, where our team builds it out with precision. Depending on the setup, our guys can assemble a complete trailer in about a day and a half.

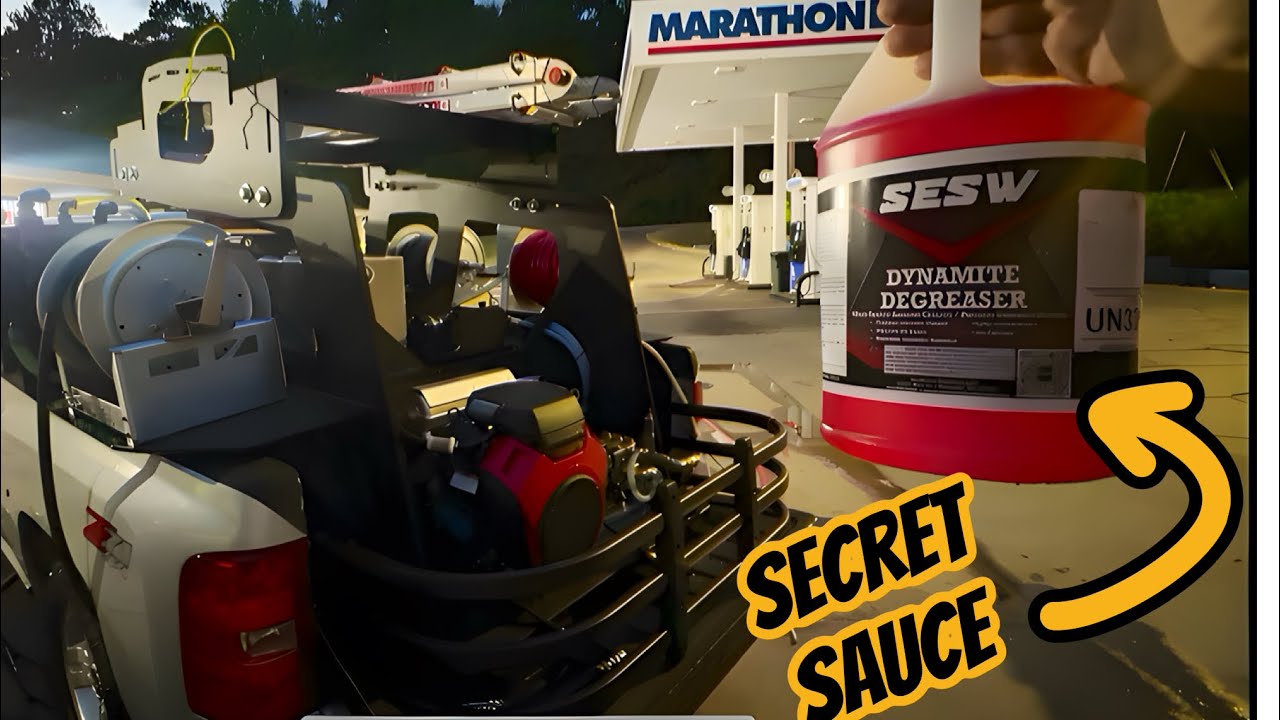

Each unit is customized based on the customer’s needs. Some trailers feature hot water machines, while others have additional storage tanks or auxiliary Downstream tanks. No matter the configuration, we take the time to ensure every hose, wire, and component is installed cleanly and logically.

-

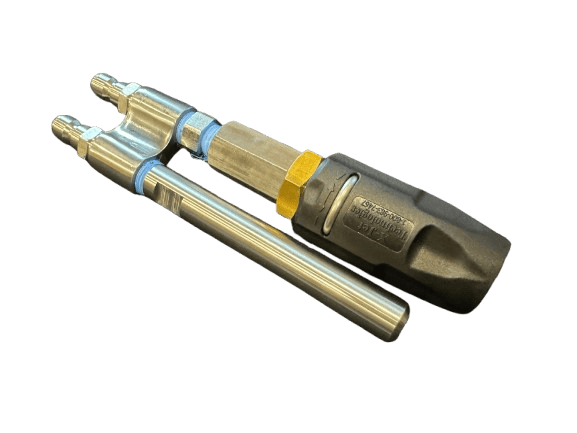

Color-Coded Plumbing & Wiring – Red for bleach, blue for water, etc., making it easy to identify components in the field.

-

Smart Stream Systems – Some units feature two pressure washers for increased efficiency.

-

Surface Cleaner Racks & Storage Solutions – Everything is designed for convenience and accessibility.

Why This Matters: Matching Equipment to Your Mission

One of the biggest mistakes I see people make is focusing too much on gear without thinking about their specific needs. The best setup for you depends on your business model—what kind of jobs you’re doing, your local market, and how you plan to scale.

For example, some of our customers opt for a hot water machine because they do a lot of commercial degreasing. Others prioritize additional tanks for different chemicals. The key is to invest in equipment that matches your mission.

That’s why we take the time to understand what you need and build trailers that are both durable and functional.

Ready to Get Your Softwash Trailer?

If you’re looking to get a trailer or skid from Southeast Softwash, now is the time to place your order. While our lead times are much shorter than they used to be, you still don’t want to wait too long. January is already picking up, and demand is growing!

Click the links below to check out our current offerings, or give us a call to get in the queue.

Serious Starter Softwash Boot Camp – March 21-22, 2025

If you’re serious about starting or growing your softwash business, I highly recommend attending the Serious Starter Softwash Boot Camp with Aaron Parker on March 21-22, 2025. This is an incredible opportunity to learn from industry leaders and get hands-on experience with top-tier equipment. Don’t miss it!

Hope you guys have a great week—go out there, make some money, and we’ll see you soon!

Peace out!