As the cold weather approaches, softwash and pressure washing pros know that winter can bring its own set of challenges. While we may enjoy the festive feel of the holiday season, the freezing temperatures can be frustrating—especially for those of us in the softwash industry. I’m here to share some crucial tips on how to winterize your softwash system, ensuring that your equipment stays in top shape even when the temperature drops.

Why Winterizing Matters

We’re based in Alabama, where winters are relatively mild. However, there are still nights when temperatures dip into the upper 20s. If your system is left outside, water can freeze and expand, potentially causing serious damage to your equipment—particularly to plastic components like metering valves and wands. Even in areas where the temperature hovers around freezing, it's important to take preventative measures.

For those living in colder climates, this is even more crucial. One of our customers in North Alabama recently experienced freeze damage because temperatures dropped into the 20s overnight, cracking a few components on his skid. Don’t let this happen to you! Winterizing can save you from costly repairs and downtime.

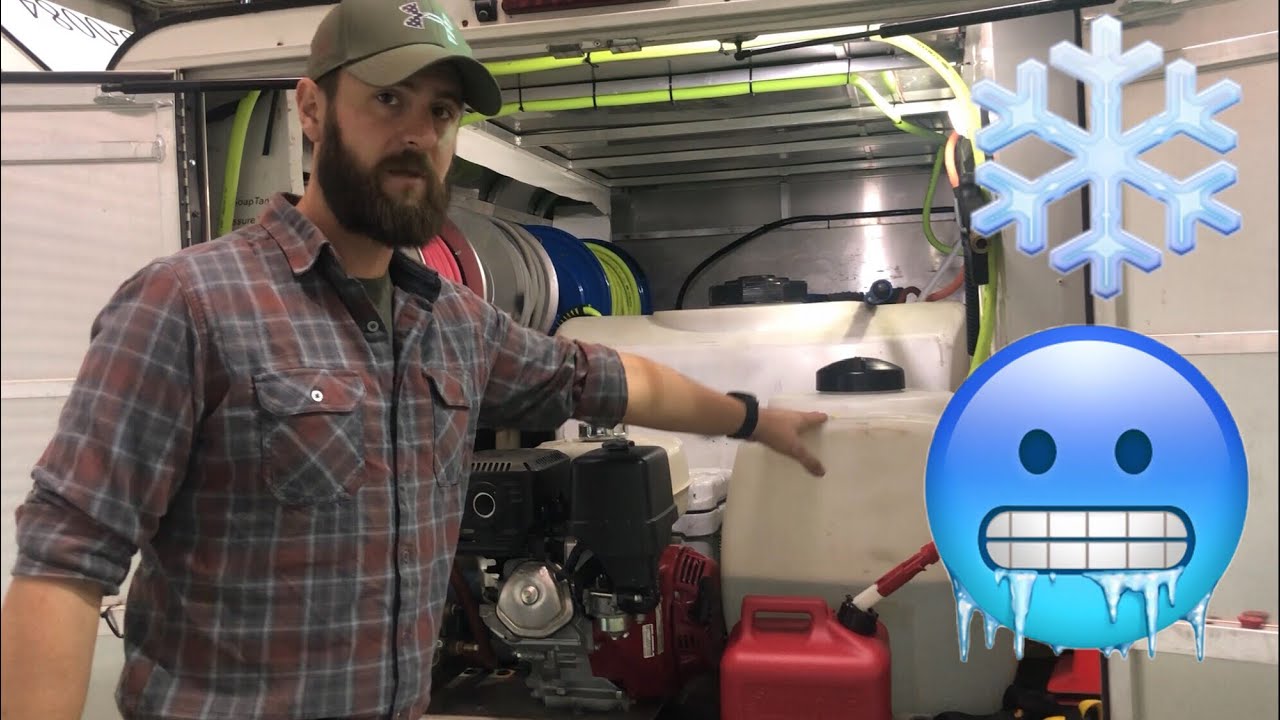

Key Steps to Winterize Your System

1. Drain the Water Tank and Lines

Start by shutting off the bleach, soap, and water lines. Then, drain as much water from the system as possible. Run the pump to force out residual water from the lines. Draining the water from the tank and lines is your first line of defense against freezing.

2. Use RV Antifreeze or Windshield Washer Fluid

Once you've drained the water, add RV antifreeze, windshield washer fluid, or any antifreeze with a low freezing point to your water tank. This ensures that any remaining liquid in your system won't freeze overnight. Run this mixture through your pump and lines until it flows out of the wand, replacing the water in the system with antifreeze.

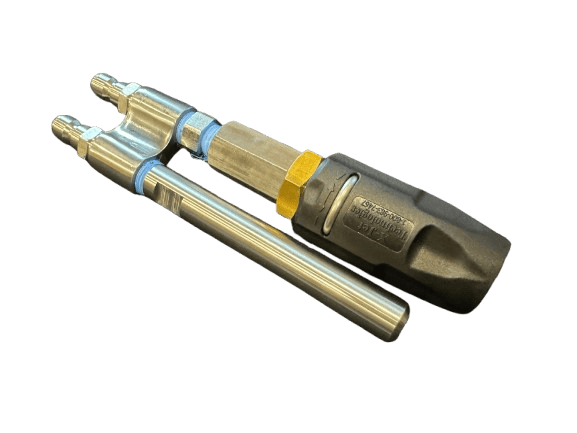

3. Focus on Vulnerable Components

The blend manifold and metering valves are particularly prone to freezing and cracking. It’s important to pay extra attention to these areas. If something does break, don’t worry—the metering valves are fairly inexpensive to replace (around $28–30). However, prevention is always better than repair.

4. Consider Indoor Storage or a Heat Lamp

If possible, store your equipment indoors during the winter months. If indoor storage isn’t an option, placing a heat lamp near your manifold and pump can help prevent freeze damage. Just be sure to drain your system after each use, especially if temperatures fluctuate between warm days and cold nights.

5. Check Your Forecast Regularly

Always keep an eye on the weather forecast! If you know a cold snap is coming, winterize your system in advance to avoid surprises. It’s a simple process that only takes a few minutes but can save you time and money in the long run.

Protect Your Business from Winter Downtime

Whether you’re in Alabama or further north, freezing temperatures can wreak havoc on your softwash equipment. By taking the time to winterize your system, you can avoid the headaches that come with frozen, cracked components and keep your business running smoothly all season long.

If you're looking to improve your softwash skills and learn more about maintaining your system, be sure to check out SESW Softwash 101. This course covers everything from equipment maintenance to advanced softwash techniques, making it the perfect resource for anyone in the softwash industry.

Don’t let winter weather slow down your business! Follow these steps to keep your equipment safe, and be sure to check out SESW Softwash 101 for expert insights and training to elevate your softwash game. Stay warm and keep hustling!