Building a blend manifold is a great way to ensure accurate ratios when applying chemicals. In this video, we'll show you how to build a blend manifold and why it's important to use the right components.

What You'll Need

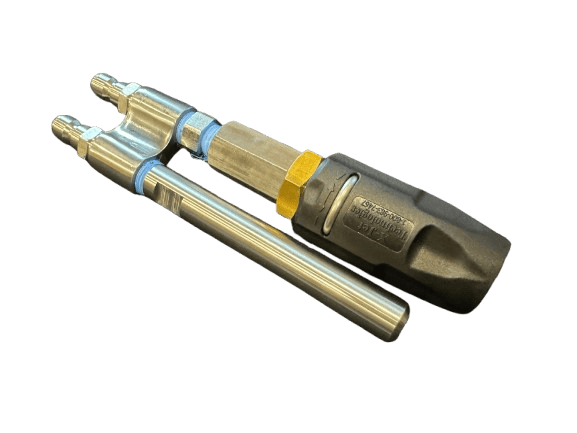

To build a blend manifold, you'll need the following components:- Batch Buster Metering valve

- Check valves

- Mixing block

- Nipples

- Barbs

- True Blue sealant

- Adjustable wrench

Step-by-Step Instructions

- Begin by attaching the barbs to the mixing block or fittings. Use True Blue sealant on the first few threads of each barb.

- Connect the nipples to the barbs. Again, use True Blue sealant on the first few threads.

- Attach the check valves to the nipples, making sure the directional arrow is pointing in the right direction.

- Attach the metering valve to the middle line.

- Attach the outlet barb to the pump.

- Use an adjustable wrench to tighten all the connections.

- Once all the connections are tight, use True Blue sealant on the remaining threads.

Why It's Important to Use the Right Components

It's important to use the right components when building a blend manifold. For example, the metering valve should be a batch Buster metering valve, as it is the only one of its kind that can become a one-inch setup as well as a 1/2 inch. Additionally, the check valves should be sized according to the leg of the manifold. Finally, it's important to use True Blue sealant, as it will create a good, clean bead around the outlet barb.

Conclusion

Building a blend manifold is a great way to ensure accurate ratios when applying chemicals. By following the steps outlined in this video, you can build your own blend manifold in about 15 minutes. Just make sure to use the right components and True Blue sealant to ensure a good, airtight seal.

Watch This Video To See Step By Step How Coty Builds A Blend Manifold

2 comments

How To Build A Blend Manifold – Step By Step – Southeast Softwash LLC

[…] post How To Build A Blend Manifold – Step By Step appeared first on Southeast […]

How To Build A Blend Manifold – Step By Step – Southeast Softwash

[…] post How To Build A Blend Manifold – Step By Step appeared first on Southeast […]