Unleash the Power of the Batch Buster™ Softwash Metering Valve

Are you looking to elevate your softwashing game with a powerful and precise metering system? Look no further than the Batch Buster™ Softwash Metering Valve, the only valve specifically designed for softwashing by the pros at Southeast Softwash. In this blog post, we'll walk you through the process of building a blend manifold using the Batch Buster™, ensuring your system is optimized for maximum efficiency and accuracy.

What is a Blend Manifold?

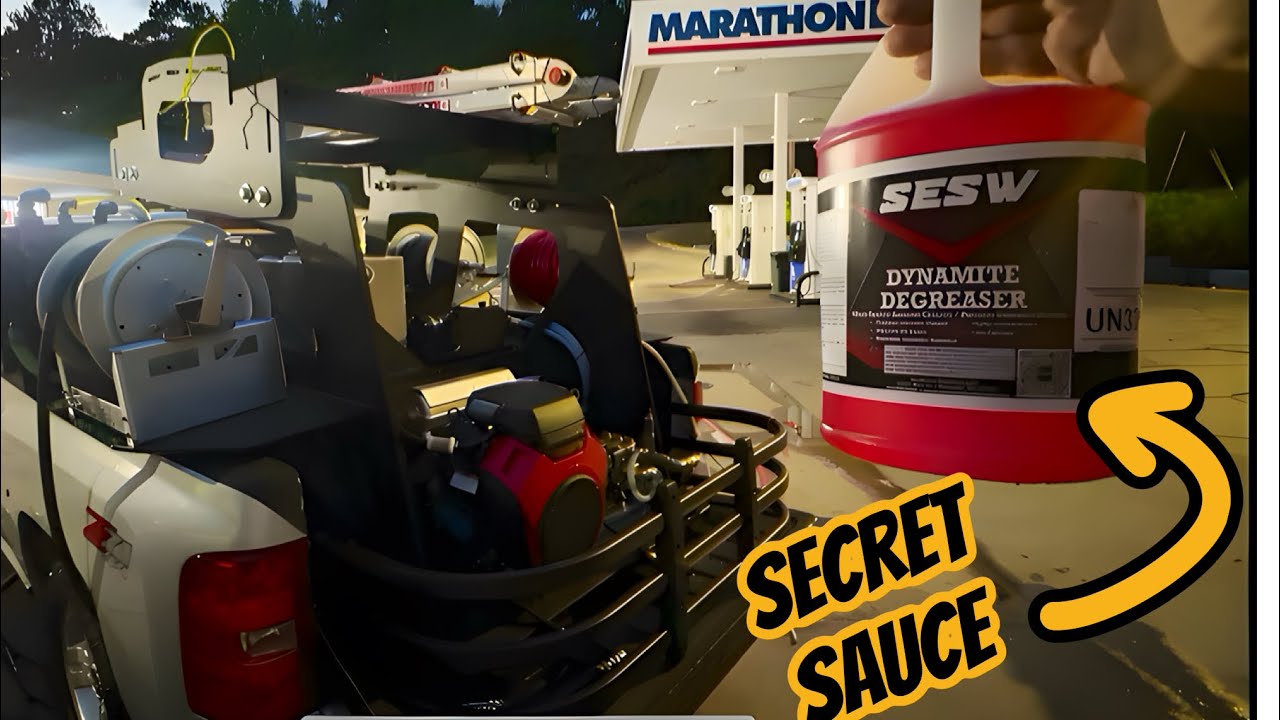

A blend manifold, also known as a proportioner, is an essential component for softwashing that allows you to mix three different chemicals—water, soap, and SH (sodium hypochlorite)—in precise ratios. The key to a successful softwash system lies in the proper assembly of these components, and the Batch Buster™ makes this process seamless.

The Batch Buster™ Difference

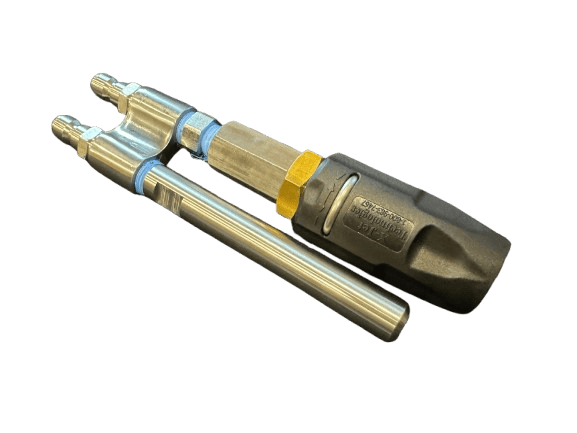

The Batch Buster™ stands out as the first and only softwash-specific metering valve on the market. It’s designed with the unique needs of softwash professionals in mind, offering features that simplify your setup and enhance your system's performance. Unlike generic valves, the Batch Buster™ ensures that your chemical mixes are consistent, your flow rates are uniform, and your system is reliable even in harsh conditions.

Step-by-Step Guide to Building a Blend Manifold

1. Gather Your Components:

- Batch Buster™ Metering Valves: You'll need three—one for bleach, one for water, and one for soap.

- Mixing Block: Choose between aluminum or poly, depending on your preference.

- Check Valves: Ensure these are in place to prevent cross-contamination between tanks.

- Barb Fittings and Nipples: Sized appropriately for your system’s flow rates.

- True Blue Sealant: For airtight connections.

2. Assemble the Manifold:

- Attach the Barbs: Coat the first few threads of the barbs with True Blue and screw them into the mixing block.

- Install the Check Valves: Ensure the directional arrow points toward the flow direction.

- Mount the Valves: Attach the Batch Buster™ Metering Valves, making sure they are properly aligned.

3. Layout Tips:

- Place the bleach line on the far right of the manifold for effective flushing after each job.

- Position the water line at the farthest point from the outlet to ensure thorough purging.

- Orient the soap line in the middle and adjust the check valve to prevent contamination during flush outs.

4. Final Assembly and Testing:

- Secure all connections and mount the manifold onto your rig.

- Test the system for leaks and ensure your valves are functioning correctly.

Why Choose the Batch Buster™?

The Batch Buster™ is more than just a metering valve; it’s a versatile solution that grows with your business. Whether you're starting with a basic 12-volt system or upgrading to a high-flow gas-powered setup, the Batch Buster™ adapts with interchangeable components, saving you time and money in the long run.

Conclusion

Building a blend manifold with the Batch Buster™ Softwash Metering Valve ensures that your softwashing system is both efficient and reliable. With Southeast Softwash’s expertise backing this innovative valve, you can trust that your setup will deliver top-notch results on every job.

Ready to build your blend manifold or upgrade your existing system? Check out the links below to purchase the Batch Buster™ and other essential components. And if you want to take your knowledge to the next level, enroll in our "How to Build a Rig" course to learn from the pros at Southeast Softwash.