What’s up, guys—Coty here from Southeast Softwash, and today we’re showing you just how fast and easy it is to swap out a Super Pump when you’re set up right and using the right gear.

Now look, we’re not swapping this pump out because it’s broken. There’s nothing wrong with it at all. We just wanted to demonstrate how quick you can get your system back up and running if you're ever in a pinch—because let’s be honest, stuff breaks in the field. It’s part of the game.

But if you’re prepared and your rig is built right, it doesn’t have to mean a whole day lost or missing out on making money.

Let’s Set the Scene…

So we’re standing by the rig, and I give the signal:

"Go!"

My guy starts the timer, and we go straight to work on swapping the pump.

It’s not a race, but let’s just say... we ain't exactly dragging our feet either. 👀

The Total Time?

⏱ 32 seconds.

Yeah, you read that right. From start to finish—pump off, pump swapped, and system back online in just over half a minute.

No scrambling, no hassle, just smooth and fast.

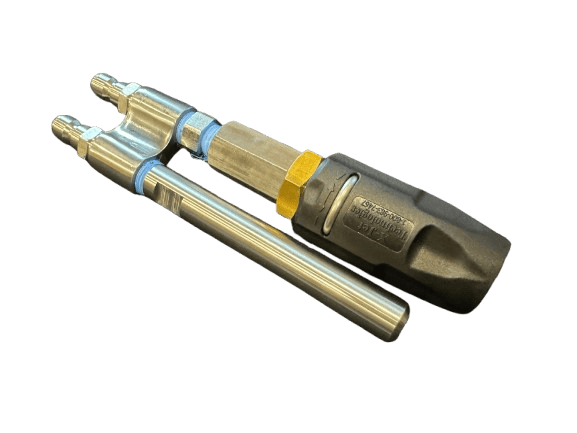

Tools Used? Just a Phillips

Now, here’s the funny part...

We didn’t use anything fancy—just a Phillips screwdriver. A flathead would’ve been even better, but Jeff wouldn’t let us steal his again (which we normally do about every 30 minutes around here 😂).

Moral of the story: You don’t need a whole toolbox to keep your softwash game tight. Sometimes the basics will do just fine—as long as you’re set up the right way.

Why This Matters

If you’re in the field doing soft washing jobs—especially residential or commercial—every minute matters.

Downtime costs money.

You got customers waiting, jobs lined up, and you can’t afford to be offline for long because a pump decided to quit on you.

That’s why we build our systems to be easy to service. You shouldn’t need an engineering degree to swap a pump or replace a part. Just grab your Phillips and get back to spraying.

Pro Tip: Plan for the Swap Before You Need It

Here’s something I always tell guys in the Lean and Mean Academy:

"Don’t wait till it breaks to learn how to fix it."

Take a few minutes on a slow day and practice your pump swap. Time yourself. Get familiar with how your system is laid out. That way, when the real moment hits, you're ready—no panic, no YouTube searches, no guesswork.

Southeast Softwash Systems = Built for Speed

This quick swap is only possible because our systems are designed for it. Whether you're running our Mini Pro, AlumiMax, or Stryker Skid, everything is laid out with field servicing in mind.

-

✅ Clear plumbing paths

-

✅ Accessible pump mounts

-

✅ Common tools only

-

✅ No weird proprietary parts

That’s how we do it down here.

Want a Rig That’s Field-Ready?

If you're tired of fighting with your current setup, come check us out. We’ve built hundreds of rigs for contractors all over the country, and they’re all designed with speed and simplicity at the core.

Because let’s face it—you’ve got money to make. And sitting around waiting on a part to get installed is just not part of the plan.

Final Thoughts

A 32-second pump swap might sound like a flex—and yeah, it kinda is—but more than that, it’s proof that a good setup makes all the difference.

You don’t need a pit crew or a mechanic on speed dial. You just need a smart build, a Phillips screwdriver, and a little prep time.

So if you're still wrenching for an hour every time something breaks, maybe it’s time to rethink the way you roll.

🔧 Build smarter. Swap faster. Make more money.

Catch y’all on the next one—don’t forget to smash that subscribe button, hit that like, and ring the bell so you don't miss more no-nonsense pressure washing content.

Let me know if you’d like this turned into a PDF job site flyer, training sheet, or even a quick IG/YouTube caption!