What's up, guys? Coty from Southeast Softwash here. Today, I’m going to walk you through a quick and easy troubleshooting session on a brand new pump from Remco. Even the best pumps can encounter issues, and this one has a bad pressure switch. Let's dive into how to diagnose and fix it.

Identifying the Problem

We buy these pumps by the pallet load because they're solid and reliable. However, from time to time, issues can arise. This particular pump isn't running because of a bad pressure switch. Here’s how we figured that out:

-

Visual Inspection:

- The pump is brand new, never been messed with, and still has epoxy over the two-millimeter screw, indicating it’s factory-fresh.

-

Initial Test:

- Plugging in the pump, it didn’t run.

- We double-checked by testing another pump in the same setup, which worked perfectly, confirming power to the pump.

Diagnosing the Pressure Switch

To confirm the pressure switch is faulty, follow these steps:

-

Apply Dielectric Grease:

- Ensure all connections are protected from the elements using dielectric grease.

-

Test the Pump:

- Flip the switch; if the pump doesn’t come on, the issue likely lies with the pressure switch.

-

Check Screws and Seals:

- Tighten all Torx screws to prevent leaks and ensure the pump is sealed correctly.

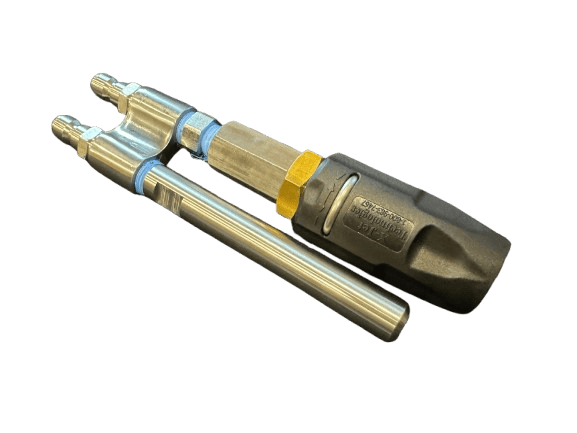

Bypassing the Pressure Switch

Sometimes, you can bypass the pressure switch to confirm it's the issue:

-

Unplug the Micro Switch:

- Detach the Honeywell micro switch.

-

Create a Jumper Wire:

- Use a jumper wire to short circuit the pump, effectively hot-wiring it.

-

Power the Pump:

- If the pump runs when bypassing the switch, you’ve identified the problem.

Fixing the Pressure Switch

If your diagnosis points to a faulty pressure switch, you have a few options:

-

Replace the Pressure Switch:

- This part can be easily replaced if the pump is under warranty or purchased separately.

-

Temporary Fix:

- In some cases, tapping on the switch can get it working temporarily, but replacement is the best solution for a long-term fix.

By following these steps, you can troubleshoot and fix a bad pressure switch on your softwash pump. Regular maintenance and quick fixes like these ensure your equipment stays in top condition, helping you avoid downtime and keep your business running smoothly.

We'll see you guys in the next video. Happy softwashing!

For more expert advice and training, check out our SESW Softwash 101 class. Become a certified applicator today and take your exterior cleaning business to the next level!