For many pressure washing businesses in the United States, winter brings a unique set of challenges. Freezing temperatures can wreak havoc on your equipment, especially when water turns to ice and causes cracks in your pumps and plumbing. In this post, we'll cover essential winterization techniques to keep your gear in top shape during the colder months. Plus, we recommend checking out the SESW Softwash 101 class for even more insights.

Why Winterization is Crucial

Water is the main ingredient in pressure washing, and when it freezes, it expands. This expansion can cause significant damage to your equipment, leading to costly repairs and downtime. Here are some essential steps to ensure your equipment survives the winter:

-

Install a Small Winterization Tank

- Use a small 10-gallon or 5-gallon tank to store antifreeze.

- Position the tank in an easily accessible area of your rig.

-

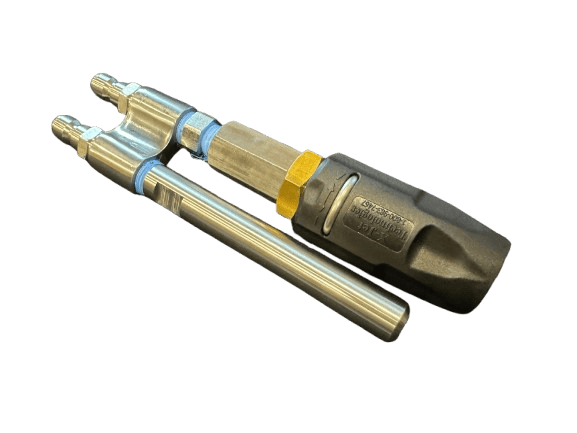

Modify Your Plumbing

- Cut the feed line and install a 90-degree ball valve.

- Connect the feed line to your winterization tank.

-

Winterize Your System

- Shut off the main water supply and open the winterization tank valve.

- Run antifreeze through the pump and hose to prevent freezing.

- Recirculate the antifreeze back into the winterization tank.

Detailed Winterization Process

Here's a step-by-step guide to winterizing your pressure washing equipment:

-

Set Up the Winterization Tank

- Position a small tank on your rig.

- Connect a hose from the tank to your feed line using a 90-degree ball valve.

-

Switch to Antifreeze

- When temperatures drop, close the main water supply valve.

- Open the valve to your winterization tank and allow antifreeze to flow through the system.

- Ensure antifreeze circulates through the pump and hoses to protect against freezing.

-

Maintain Proper Antifreeze Levels

- Use washer fluid or antifreeze in your winterization tank.

- Add 2-3 gallons to keep the system from freezing, adjusting based on the water volume.

-

Protect Your Fittings

- Regularly check fittings, especially banjo filters, for cracks and leaks.

- Replace damaged fittings to avoid air leaks and pump issues.

Alternative Income During Winter

For those in regions where pressure washing isn't feasible during winter, consider diversifying your services. One lucrative option is Christmas light installation. We've teamed up with Glenn Jernigan, who generates $150,000 annually from November to January through this service. Join our five-day digital boot camp to learn how to sell, install, and maintain Christmas lights effectively. The link is in the description and comments.

Conclusion

Winterizing your pressure washing equipment is essential to avoid costly repairs and downtime. By following these steps, you can ensure your gear remains in top condition throughout the colder months. For a deeper dive into pressure washing techniques and strategies, be sure to check out the SESW Softwash 101 class. Stay prepared and keep your business thriving, even in winter!

By properly winterizing your pressure washing equipment, you can minimize downtime and maintain the integrity of your tools. Join the SESW Softwash 101 class for more expert advice and strategies to keep your business running smoothly year-round.