Hey everyone, welcome back to the Lean Mean Academy! Today, we're diving into a troubleshooting guide for your pressure washing skid. This post will walk you through a common issue with check valve failure and how to fix it. Plus, don't miss out on our recommendation to check out the SESW Softwash 101 class for more in-depth training on pressure washing and soft washing.

The Issue: Blue Dye in the Bleach Line

We were prepping a skid for a customer and testing out a new surfactant with a marking dye. Everything seemed fine until we noticed the line to the bleach tank turning bright blue, indicating a problem.

Diagnosis: Check Valve Failure

After some inspection, we discovered that the check valve had failed. This usually happens when debris, such as tiny plastic shards, gets lodged inside the valve, preventing it from sealing properly.

Step-by-Step Troubleshooting and Fix

-

Identify the Problem:

- We noticed the surfactant line was bright blue, which was expected.

- However, the bleach tank line also turned blue, indicating cross-contamination.

-

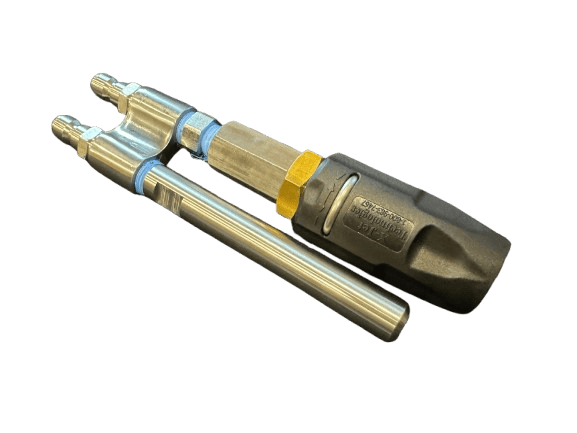

Check the Check Valve:

- We popped off the hose and inspected the check valve.

- Inside, we found a small piece of plastic debris causing the issue.

-

Clean the Check Valve:

- Disassemble the check valve using wrenches.

- Remove the debris and inspect the plunger and seal for any damage.

- Clean out any remaining particles to ensure a clear path.

-

Reassemble and Test:

- Carefully reassemble the check valve.

- Heat the hoses slightly for easier attachment.

- Refill the rear tank with water and test the system.

-

Verify the Fix:

- Ensure that the surfactant and bleach lines remain clear when the system is running.

- Confirm that the issue was resolved and no further cross-contamination occurs.

Key Takeaways

- Debris in the Check Valve: Even a tiny piece of plastic can cause the valve to fail. Always keep your lids on and clean out your tanks regularly.

- Routine Testing: Regularly run and test your skid before sending it out to catch any issues early.

- Effective Troubleshooting: A systematic approach to troubleshooting can save you time and prevent bigger problems down the line.

Final Thoughts

By following these steps, you can quickly diagnose and fix common issues with your pressure washing skid. Remember, regular maintenance and cleanliness are crucial to keeping your equipment running smoothly.

For more tips, strategies, and comprehensive training on pressure washing and soft washing, be sure to check out the SESW Softwash 101 class. It's an excellent resource for both beginners and experienced professionals looking to enhance their skills.

Stay tuned for more troubleshooting guides and tips from the Lean Mean Academy. Happy cleaning!