Hey guys, welcome back! Today, we’re diving into a real-world example of a soft wash trailer that’s experiencing some issues. One of our Softwash 101 class attendees brought in his setup, which wasn’t working as intended, and we identified a few key problems that anyone in the soft wash industry should be aware of.

If you're just getting started or already working in soft washing, make sure you check out our SESW Softwash 101 class—it covers essential tips for avoiding costly mistakes like the ones we’ll talk about here.

Common Setup Problems in Soft Washing

This trailer wasn’t built by us, but we were able to help the owner troubleshoot a few major issues. The setup had inconsistencies that were causing air leaks and inconsistent chemical ratios. Let’s go over the two main problems we found:

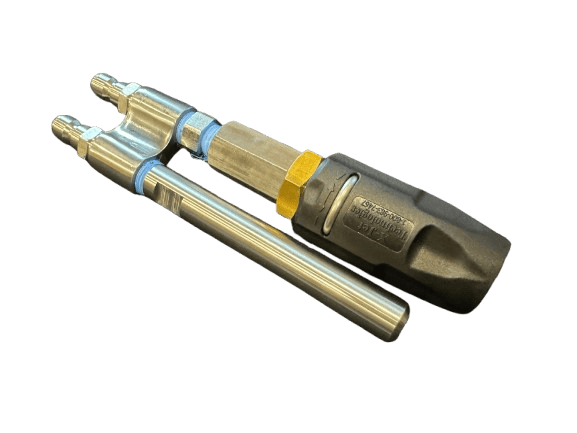

1. Improper Metering Valves

The first thing we noticed was the use of an open ball valve on the water intake instead of a proper metering valve. The ball valve has no internal restrictions, meaning the system pulls more water than chemicals, making it nearly impossible to achieve accurate chemical mixes. This leads to inconsistent cleaning results.

When we build systems, we always use metering valves for both chemicals and water to ensure uniformity and accuracy. Spending an extra $100 or $150 for the right equipment from the start will save you a ton of headaches down the road.

2. Poor Mounting and Vibration Issues

The second issue we spotted was the lack of proper mounting points. Because the system wasn’t securely bolted down, the vibration from the trailer and gas engine caused movement, leading to air leaks at multiple points. Even though one of the components had the capability to be mounted, it wasn’t. Over time, this caused additional wear and tear, resulting in more leaks.

If you’re building or purchasing a trailer, make sure your components are mounted securely. Soft wash trailers experience constant vibration from driving and engine operation, and poorly mounted parts will inevitably fail.

The Right Way to Build a Soft Wash System

We don’t want to bash on anyone, but this is a clear example of why it’s important to either build your rig the right way or get it from a builder who knows their stuff. When we design systems at Southeast Softwash, we ensure every valve, pump, and component is mounted securely, using high-quality parts that are built to last.

We also design our setups to minimize vibration and air leaks. The difference between a professionally built system and a poorly designed one is reliability and longevity—key factors that will affect your business's bottom line.

Learn the Right Way with SESW Softwash 101

Want to avoid these kinds of issues entirely? Our SESW Softwash 101 class will teach you everything you need to know about soft washing, including how to set up and maintain your equipment properly. You’ll gain hands-on experience and learn the ins and outs of building a reliable, professional-grade soft wash system.