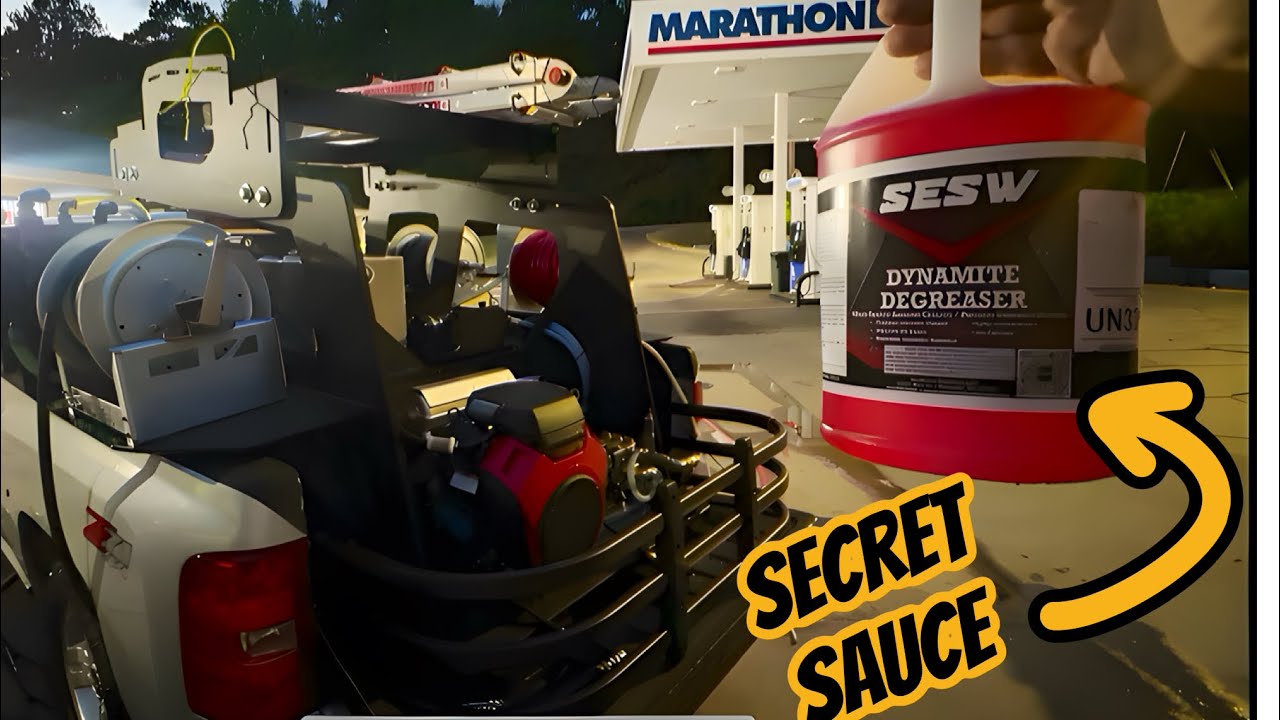

Hey Southeast Softwash family! We're gearing up for the Serious Starter Softwash Boot Camp with Aaron Parker this February 21-22, 2025. But before we dive into what makes this event a must-attend, let’s take a moment to share a troubleshooting lesson from the field. This real-world example highlights why proper training and system design are critical for your success.

Troubleshooting a Competitor’s Trailer Build

Recently, during one of our Softwash 101 classes, a participant brought their competitor-built trailer for some troubleshooting. Despite being a new system, it had already started failing after just two jobs. Let’s break down the issues and the lessons learned:

Concept-Level Issues

-

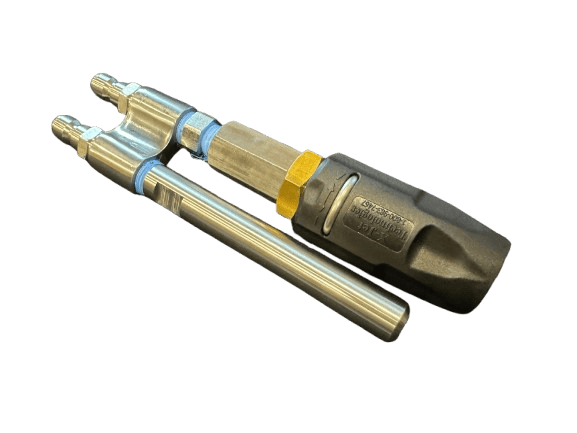

Lack of Metering Uniformity

-

The system used metering valves for chemicals but skipped metering on the water supply, opting for a standard open ball valve. This design flaw creates inconsistent ratios, leading to inefficiencies.

-

Solution: Use metering valves across all inputs, including water. Uniformity ensures precision and avoids costly mistakes. Spending an extra $100-$150 upfront for the right setup pays off in the long run.

-

-

Inadequate Mounting Points

-

The trailer’s ball valves lacked secure mounting, causing them to vibrate and develop air leaks within weeks. One side didn’t have mounting capabilities, and the other side wasn’t bolted down despite having the option.

-

Solution: Always secure components with proper mounting to prevent vibrations and leaks. Engineering out potential failure points is essential for durability, especially in mobile setups.

-

Execution Failures

-

Ignoring Structural Design

-

Smaller valves were not aligned with the back wall, making it impossible to bolt them securely. This oversight compromised the system’s stability.

-

Solution: Offset components during the design phase to ensure everything can be securely attached to a mounting plate.

-

-

Cutting Corners

-

Poor component choices and assembly shortcuts led to an air leak on two lines of the system.

-

Solution: Invest in quality materials and take the time to assemble systems correctly. Rigorous attention to detail is non-negotiable.

-

Key Takeaway

Not all trailer builds are created equal. Some builders are learning on the job—often at the expense of their customers. When you invest in a rig, ensure it’s built by experienced professionals who prioritize performance and durability.

Why Attend the Serious Starter Softwash Boot Camp?

This hands-on boot camp is perfect for anyone starting their softwash journey or looking to sharpen their skills. Here’s what you’ll gain:

-

Expert Instruction: Learn directly from Aaron Parker and the Southeast Softwash team.

-

Real-World Scenarios: Gain insights from troubleshooting real systems, just like the example above.

-

Build Confidence: Walk away with the knowledge and skills to design, operate, and troubleshoot your softwash systems effectively.

Event Details:

-

Dates: February 21-22, 2025

-

Location: Southeast Softwash Headquarters

Don’t Miss Out!

The Serious Starter Softwash Boot Camp is your chance to learn from the best and set yourself up for success in the softwashing industry. Spots are limited, so secure yours today!

Let’s make 2025 the year you elevate your softwash game. See you at the boot camp!