Winterizing Your Soft Wash System: Key Tips for Protecting Your Equipment

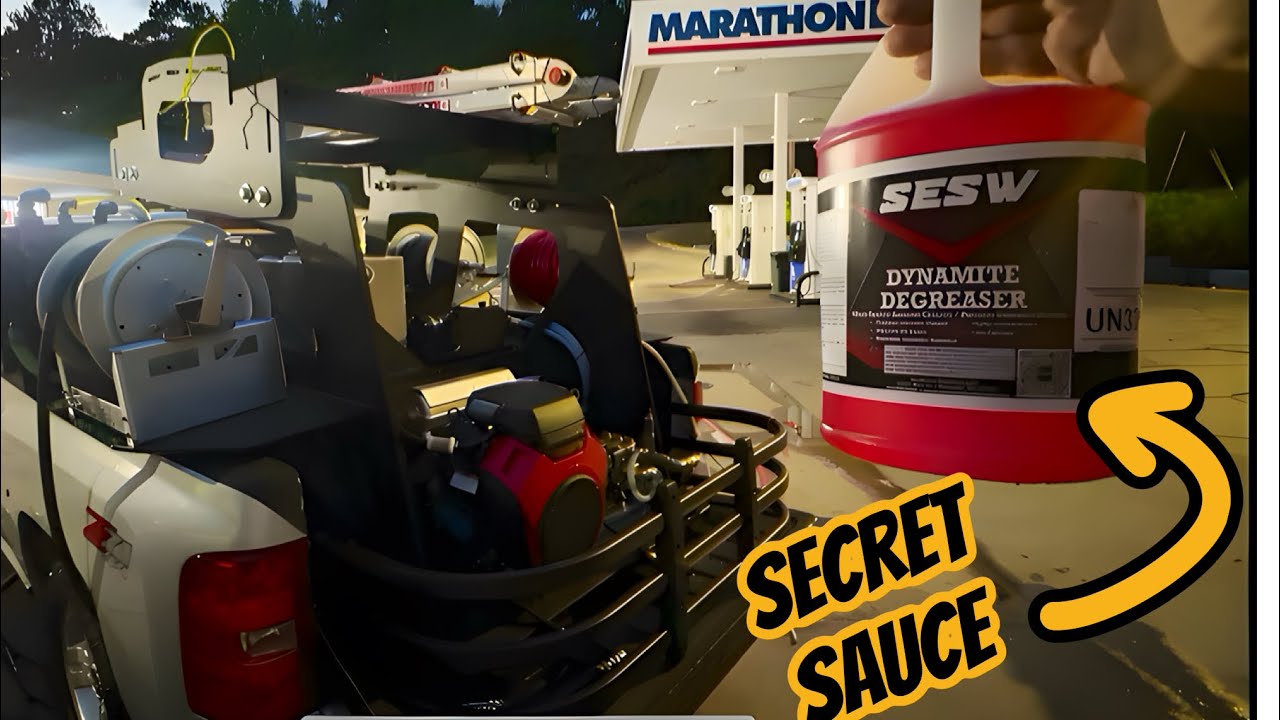

Hey guys! As we step into February, it’s important to remember that winterizing your soft wash system is crucial, especially for those living in colder climates. Even in areas like Georgia and the Southeast, where we get mild temperatures during the day but freezing nights, protecting your equipment can save you from costly repairs and downtime.

Why Winterizing Matters

Water freezes, and when it does, it expands—this can cause cracks in your pumps, wands, and sensitive components. Whether you're using a soft wash system or a pressure washer, taking steps to winterize your equipment can keep it safe from cold damage and ensure you’re ready for business when warmer weather rolls around.

In colder northern states, many businesses shut down during winter, storing their gear until spring. But for those of us in areas with fluctuating temperatures, we often want to jump back into work during the warmer days, making winterizing an even more frequent challenge.

Winterizing Best Practices

-

Antifreeze Is Your Best Friend

Run antifreeze through your system to ensure water doesn’t freeze in the lines. Even if you’re only planning on storing your system overnight, this simple step can prevent significant damage. -

Heat Lamp Method

If you're operating in regions where it’s cold at night but warm enough during the day to work, using a heat lamp on sensitive components like the pump and manifold can help. Be careful! As I discussed in the video, if the lamp is placed too close, it can melt plastic parts, leading to costly repairs.A quick tip—give it 15 minutes and check the distance between your heat lamp and the components to avoid overheating anything sensitive. The goal is to keep the critical components from freezing without causing damage.

-

Indoor Storage

If possible, storing your equipment in a building overnight can save you from the daily cycle of loading your system with antifreeze, draining it, and then refilling it with chemicals every morning. -

Careful with Heat Sources

If you’re using a heat lamp, ensure it’s far enough away from plastic parts or fuel containers. There have been cases where entire trailers and even vans have caught fire due to heat lamps being placed too close to flammable items.

A Costly Mistake to Avoid

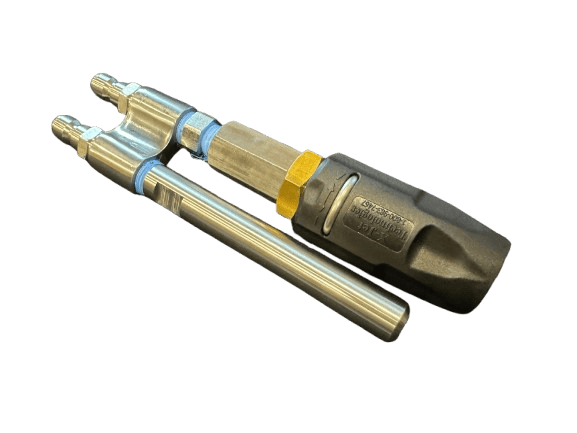

In this video, we showed how a simple mistake with a heat lamp melted part of a soft wash system. These GF valves, which are critical for soft wash setups, are not cheap! It’s an expensive lesson, but it happens—so always monitor your heat source carefully.

Ready to Learn More?

If you’re new to the soft wash industry and want to dive deeper into techniques, equipment maintenance, and proper winterization, now is the perfect time to up your game. The SESW Softwash 101 Class is an excellent resource for anyone looking to gain hands-on knowledge from industry experts. We cover everything you need to know, from basic setups to advanced strategies, ensuring that your business stays ahead—no matter the season.

Don’t let cold weather set you back. Get equipped with the right skills and knowledge by checking out the SESW Softwash 101 Class today!

Meta Description: Learn how to winterize your soft wash system to protect your equipment. Check out SESW Softwash 101 Class to further enhance your skills and prepare your business for success.