In the world of soft-washing, efficiency is key. Whether you’re dealing with stubborn stains on high surfaces or just looking to optimize your setup, the SESW Super Pump is the tool that can take your business to the next level. Let’s dive into why this game-changing equipment should be your next investment—and how to avoid common pitfalls like pump cavitation and premature failures.

Why the SESW Super Pump Is a Game-Changer

The SESW Super Pump brings together the best of all worlds in soft-washing. It offers the ease of an electric system combined with a powerful 16 GPM max flow, making it a true beast in the washing world. Whether you're aiming to hit over five stories vertically or need to throw water up to 75 feet, this pump delivers performance that was previously unheard of.

What really sets the SESW Super Pump apart, though, is its efficiency. With the ability to do a complete pump swap in under one minute, without the need for any tools, you can minimize downtime and keep your operations running smoothly. The revolutionary speed control version offers an infinite adjustable power selection knob, allowing you to tailor your chem application and rinsing power with precision. This means less chemical waste and more savings for you.

Avoiding Common Pump Pitfalls

One of the biggest issues soft-wash professionals face is pump cavitation—when the pump's pressure fluctuates due to air pockets or debris in the water supply. This not only affects your washing results but can also lead to premature pump failure. Recently, we encountered this issue firsthand during a surface cleaning job. The pump was cavitating like crazy, with pressure pulsing in and out, causing major headaches.

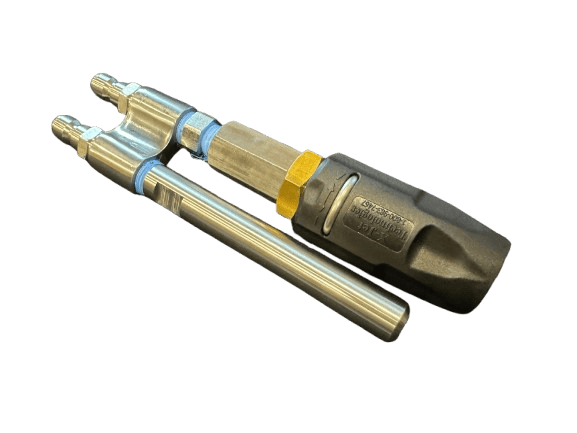

The culprit? A dirty water tank without an inline filter. Without this crucial component, muck from the tank made its way into the pump, causing the check valve to malfunction. To avoid this costly mistake, always install an inline filter in your water supply line. Not only does it prevent debris from reaching your pump, but it also prolongs the life of your equipment, saving you from unnecessary downtime and repair costs.

Installation Tips: Keeping Your Flow Smooth

When installing your inline filter, make sure to avoid sharp turns in your water supply lines. This can restrict flow and cause additional issues. Polypropylene, while stronger and more crack-resistant than PVC, can still crack if over-tightened, so apply your thread sealant carefully and avoid going overboard.

Another crucial tip: pay attention to the direction of flow when installing your filter. The arrow on the filter should always point towards the pump and away from your tank. This simple step ensures that your water flows correctly and maintains consistent pressure.

Finally, if you encounter air in your lines, loosen the filter slightly to let water start flowing before tightening everything back up. This will help maintain smooth operation and prevent cavitation.

Elevate Your Soft-Wash Game with SESW Super Pump

The SESW Super Pump is more than just a tool—it’s a game-changer for soft-wash professionals who want to maximize efficiency, reduce chemical waste, and eliminate common pump problems. By pairing this powerhouse with proper installation and maintenance practices, you can ensure your soft-wash setup runs smoothly, delivering top-notch results every time.

Ready to take your business to the next level? Equip yourself with the SESW Super Pump and experience the difference.