Hey folks, Coty from Southeast Softwash here! Today is March 21st, and we're excited to share one of our large commercial cleaning projects with you. We're out here taking advantage of the nice weather to clean a local high school gymnasium. Let's dive into the details of this project and the innovative techniques and equipment we're using to get the job done efficiently.

The Project Overview

This high school gymnasium features a classic combination of metal and brick on the lower section of the building. This setup is common in many warehouses and metal buildings, making this project a great case study for similar commercial cleaning jobs.

The north side of the building was particularly dirty, with a lot of organic growth that needed attention. Check out the before-and-after screenshots and b-roll footage to see how nasty it was before we started cleaning.

Cleaning Techniques and Solutions

When cleaning metal surfaces, we don't need a strong mix because the slick surface means the dirt and organic growth are just sitting on top. For this project, we used a 2% mix to clean the metal sections and then rinsed it off.

As we moved to the stucco sections, also known as Dryvit or EIF panels, we had to increase the strength of our cleaning solution to about 4%. The porous nature of stucco allows organics to grab a foothold, requiring a stronger mix for effective cleaning. The front of the building was particularly dirty on the stucco side, as you can see from the additional shots we've included.

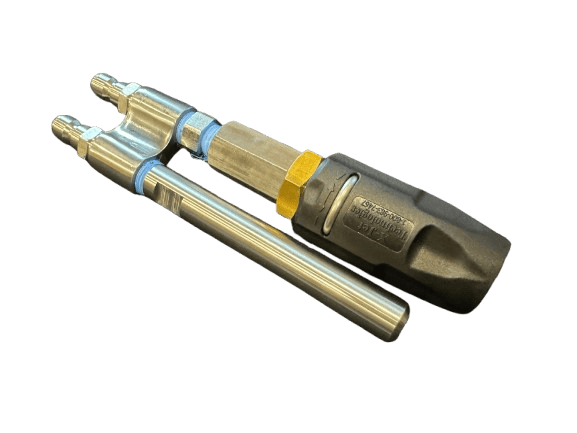

Innovative Equipment: Smart Blend

In the past, switching between different cleaning solutions for metal and stucco would mean walking back to the work truck every time to adjust the ratios. This process was time-consuming and inefficient. However, with our handy dandy Smart Blend system working on our 24-volt pump, we can now change our ratios on the fly, ranging from 1% to 6%.

Not only can we adjust the cleaning solution strength, but we can also change the soap levels from low, medium, and high, or shut it off entirely to switch to water-only rinsing. This flexibility allows us to rinse the building efficiently without making constant trips back to the truck.

Rinsing Techniques

We use a ball valve on the pressure washer for rinsing, but with two guys on the job, we can double team the rinsing process and knock out the project faster. This teamwork, combined with our advanced equipment, ensures we deliver high-quality results in less time.

Final Thoughts

We're almost done with this project, and we wanted to share this update with you. The right techniques and equipment can make a huge difference in the efficiency and effectiveness of commercial cleaning projects. Stay tuned for more updates and insights from Southeast Softwash!

We'll see you in the next video. Until then, keep hustling and getting that money, baby! Peace.

By using the right techniques and equipment, Southeast Softwash ensures that commercial cleaning projects, like this high school gymnasium, are completed efficiently and effectively. Whether you're dealing with metal or stucco surfaces, having the ability to adjust cleaning solutions on the fly can save you time and effort. Check out our videos and stay tuned for m