Hey there, Coty from Southeast Softwash here! Today, we're diving into the nuts and bolts of building a blend manifold—a crucial component for any soft washing setup. We’ve got a few examples behind us, including our latest innovation, the Batch Buster setup. This guide will walk you through the process of assembling your own blend manifold, ensuring you get the best performance out of your soft washing system.

Before we dive into the details, I want to give you a heads-up about our new course, "How to Build a Rig." It's perfect for those who want to get into the business but can’t afford a turnkey system. The course covers everything from start to finish—frame, trailer, skid, wiring, plumbing, material selection, and more. Check the description for a link to the course!

What is a Blend Manifold?

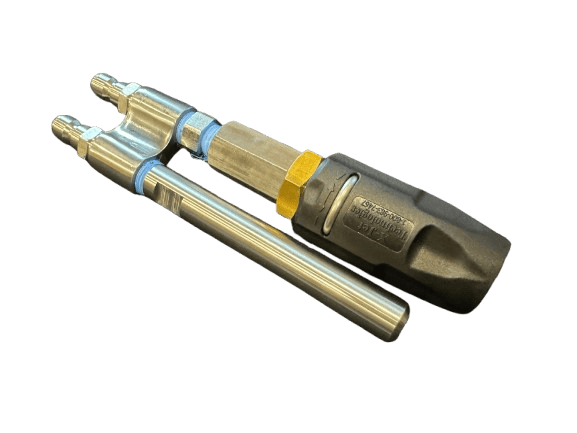

A blend manifold, also known as a proportioner, is a setup that mixes three different chemicals—water, soap, and SH (sodium hypochlorite). The goal is to create a system that allows you to adjust the ratios of these chemicals on the fly, ensuring optimal performance for different cleaning tasks.

Tools and Materials You'll Need

- GF blend manifold or Chemline valves

- Batch Buster metering valves (soft wash-specific)

- True Blue sealant (liquid pipe dope)

- Adjustable wrench

- Aluminum or poly mixing block

- Half-inch nipples

- Check valves (one-way valves)

- Barbs (half-inch and/or three-quarter-inch, depending on your system)

- Metric bolts for mounting

Step-by-Step Assembly

1. Prepare Your Work Area

Set up your workbench with all the components laid out. Make sure you have a clear space to work and all your tools within reach.

2. Assemble the Components

Start by coating the first few threads of your barbs with True Blue sealant. This will ensure a tight, leak-free connection. Screw the barbs into the mixing block, and use your adjustable wrench to tighten them securely.

3. Attach the Check Valves

Next, attach the check valves to the barbs. Ensure the directional arrow on the check valves points in the direction of flow. This step is crucial to prevent cross-contamination of your chemicals.

4. Connect the Metering Valves

For the surfactant line, attach the metering valve directly to the check valve. For the water and bleach lines, follow the same procedure, ensuring all connections are sealed with True Blue.

5. Secure the Manifold

Mount the completed manifold to your rig using the metric bolts. Ensure all components are secure and there are no loose connections.

6. Test Your System

Once assembled, run a test to ensure there are no leaks and that the system functions correctly. Adjust the metering valves to check the flow and ratios of your chemicals.

Tips for Optimal Performance

- Orientation Matters: Place your bleach line on the far right and your water line furthest from the outlet to optimize the flush-out process.

- Use True Blue Sealant: Avoid using Teflon tape. True Blue sealant provides a better, more reliable seal.

- Regular Maintenance: Disassemble and clean your manifold every 12 to 18 months to ensure peak performance.

Why Choose the Batch Buster Valve?

Our Batch Buster valve is the only soft wash-specific metering valve on the market. It’s designed to handle the harsh chemicals used in soft washing, ensuring durability and reliability. Plus, it can be easily upgraded from a half-inch to a one-inch setup, saving you money in the long run.

Conclusion

Building a blend manifold might seem daunting, but with the right tools and a bit of know-how, you can create a system that meets your needs and boosts your efficiency. Whether you're just starting or looking to upgrade your existing setup, this guide provides the essential steps and tips to get you there.

If you're interested in learning more about building your own rig, don't forget to check out our course linked below. And if you prefer to buy pre-assembled components, we've got you covered—links are in the description.

Happy soft washing, and see you in the next video!